- Shop

- About

- Products

- 6mm X 6mm X 6mm Barbed Overhead Gas Bracket

- 9.5mm X 6mm X 9.5mm Barbed Overhead Gas Bracket

- 6mm Tee - N/A In Nsw

- 10mm X 6mm X 10mm Tee - N/A In Nsw

- Self Re-Coil Gas Hose

- Gas Bottle Bracket

- Co2 Gas Bottle Holder (Small)

- Cellarwarn Monitor

- R.30 Gas Washer (Nylon Or Poly)

- R.31 Gas Washer (Nylon)

- Harris Gas Washer

- Andale Cold Plate - Single

- Cold Plate – Double

- Cold Plate Cooler Pack – Double

- Cold Plate Cooler Pack – Single

- Cold Plate Cooler – Double

- Cold Plate Cooler – Single

- Deluxe Cold Plate Cooler Pack – Single

- Deluxe Cold Plate Cooler Pack – Double

- Deluxe Cold Plate Cooler – Single

- Deluxe Cold Plate Cooler – Double

- Delux Cooler With Font

- Co2 Small Gas Bottle Holder

- Flexidraft™ Copenhagen Tower Single Font With Illuminated Round Frog Eye Lens

- Flexidraft™ Copenhagen Tower Single Font With Illuminated Round Frog Eye Lens - Short Version

- Flexidraft™ Copenhagen Duo Tower Chrome Without Illumination

- Flexidraft™ Wall Tap Set

- Flexidraft™ Drip Tray Small

- Flexidraft™ Drip Tray Medium

- Manufacturing

- Service

- Installations

- Shop

- About

- Products

- 6mm X 6mm X 6mm Barbed Overhead Gas Bracket

- 9.5mm X 6mm X 9.5mm Barbed Overhead Gas Bracket

- 6mm Tee - N/A In Nsw

- 10mm X 6mm X 10mm Tee - N/A In Nsw

- Self Re-Coil Gas Hose

- Gas Bottle Bracket

- Co2 Gas Bottle Holder (Small)

- Cellarwarn Monitor

- R.30 Gas Washer (Nylon Or Poly)

- R.31 Gas Washer (Nylon)

- Harris Gas Washer

- Andale Cold Plate - Single

- Cold Plate – Double

- Cold Plate Cooler Pack – Double

- Cold Plate Cooler Pack – Single

- Cold Plate Cooler – Double

- Cold Plate Cooler – Single

- Deluxe Cold Plate Cooler Pack – Single

- Deluxe Cold Plate Cooler Pack – Double

- Deluxe Cold Plate Cooler – Single

- Deluxe Cold Plate Cooler – Double

- Delux Cooler With Font

- Co2 Small Gas Bottle Holder

- Flexidraft™ Copenhagen Tower Single Font With Illuminated Round Frog Eye Lens

- Flexidraft™ Copenhagen Tower Single Font With Illuminated Round Frog Eye Lens - Short Version

- Flexidraft™ Copenhagen Duo Tower Chrome Without Illumination

- Flexidraft™ Wall Tap Set

- Flexidraft™ Drip Tray Small

- Flexidraft™ Drip Tray Medium

- Manufacturing

- Service

- Installations

KEG VALVES & PACKAGING

TRUSTED IN OVER 120 COUNTRIES

As the trusted leader in keg spear technology around the world, Micro Matic is dedicated to providing market-leading innovations, proven quality and best-in-class service.

For us, commitment to high quality means reliability, durability and safety are instilled in every part and piece we produce and ship. In an age where shortcuts are common, we always ensure you’re getting the best.

From our rigorous, multi-step testing performed on 100% of keg spears produced, to our comprehensive warranties, we are committed to providing the very best to our customers.

NEXT GENERATION SPEARS

SERVICES LIKE NO OTHER

120 million keg spears produced

and delivered since 1969

Micro Matic keg spears are installed

in 90% of the world’s kegs

NEW KEG SPEARS

Andale Micro Matic D System (aka American Sankey) Keg Spears are available to every keg manufacturer world-wide, and new/replacement keg spears are available for your used kegs. Insist on Micro Matic keg spears to be installed in the kegs you purchase as new.

Contact us to order new spears and for assistance in sizing, keg neck type identification and the exact version of the D System spear you need for kegs you already own.

KEG SPEARS

NEXT GENERATION KEG SPEARS

YOUR SAFETY IS OUR RESPONSIBILITY

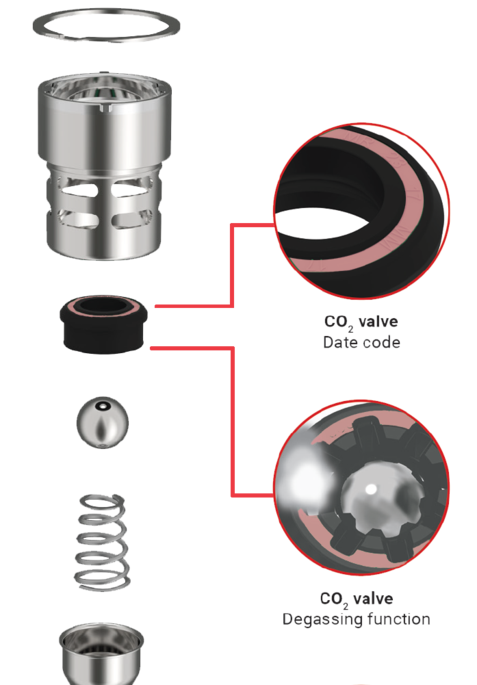

Safety features are our top design priority toward eliminating accidental or unauthorized removal of spears or tampering that could result in injury. With color and year coding, we offer a means of segregating kegs for preventive maintenance.

Micro Matic spears are manufactured in stainless steel and are engineered for maximum strength, hygiene, and quick filling providing long-life durability in all conditions.

125 MILLION SPEARS - AND STILL COUNTING

Micro Matic has produced more than 125 million keg spears over the last 40 years. With market-leading innovations, proven quality and best-in-class service, Micro Matic is the trusted leader in keg spear technology.

INNOVATIVE ADVANTAGES

WHAT IS COLOR CODING?

The market-leading spear from Micro Matic comes with a unique color and year coding for preventive maintenance.

Color-coding of the spears enables camera-controlled or mechanical separation of kegs that are due for routine, scheduled maintenance which Micro Matic recommends at approximately 7-8 year cycles.

In 2019 the color-code was yellow; in 2020 it is Rose Pink, and in 2021 it will be Violet. (Note that there will be a 3-4 month transition period each year from one color to the next).

Below you can find the color markings for the coming years:

THE DETAILS THAT MAKE THE DIFFERENCE

INNOVATION UNIQUE TO MICRO MATIC KEG SPEARS:

Safety pressure-release feature of spears allows the controlled deformation of the CO2 gasket without dangerous ejection of valve parts.

Retainer disc redesign for enhanced cleanability and sanitation eliminating internal flat metal-on-metal parts interface.

FAQS

For All Keg Spear Enquiries contact

2/2 Pile Street · Somersby · NSW · 2250 Australia