- /

- Glycol Beer System

Glycol Beer System

Glycol Beer System

A Glycol beer dispensing system is the latest in beer dispensing technology. A Glycol system is an excellent alternative or upgrade from an old Temprite or Ice Bank beer system. Andale’s Glycol Block Beer System was one of the first true glycol beer systems in the Australian market place.

How Does an Andale Glycol Beer System Work?

A Glycol beer dispensing system is the latest in beer dispensing technology. A Glycol system is an excellent alternative or upgrade from an old Temprite or Ice Bank beer system. Andale’s Glycol Block Beer System was one of the first true glycol beer systems in the Australian market place.

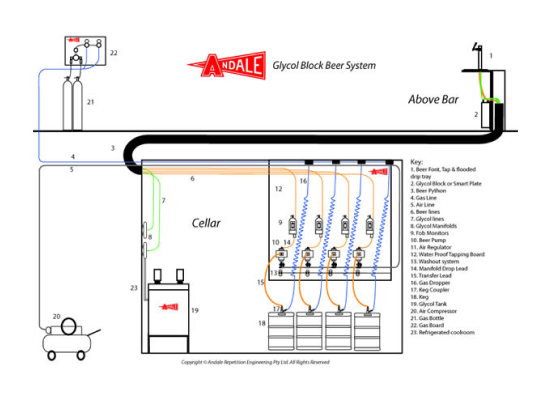

A Glycol tank is placed in a refrigerated cool room. Using beer python, minus degree glycol is constantly circulated through the python, glycol block, font and back to the glycol tank.

This results in a system where beverages are kept at a constant temperature from the keg to the beer tap, dramatically slowing the growth of wild yeast and bacteria in your beer lines and reducing beer wastage.

Beer Python

Beer python is a cluster of beer and glycol lines bundled together and wrapped in plastic to form a vapour seal encased in insulated foam. The foam is used to minimise heat gains over the length of the python. Andale’s beer python is made exclusively in our production facility in Somersby, NSW.

Glycol

Glycol is an antifreeze agent which allows water to cool below zero degrees without freezing. Propylene is non-toxic and is used exclusively in Andale’s Glycol Block Beer Dispensing Systems. Propylene Glycol is manufactured from propylene oxide and is used in foods, cosmetics and oral hygiene products as solvents, preservatives and moisture retaining agents.

Flooded Font

The flooded font was first introduced by Andale in the early 1990’s. A flooded font is any form of font where glycol or water can flow through the inside of the font, cooling and stabilizing the drink within the font. The flooded font helps to ensure your beer is chilled right up to the dispensing point preventing any possible ‘hot spots’ in your dispensing system.

Ice Formation on the Font

In most situations glycol between –2 and –3.5 degrees is flowing through the font. Condensation forms from moisture in the air, which then freezes because the glycol flowing within the font has a lower freezing point than water. Ice formation cannot be guaranteed in a standard glycol system

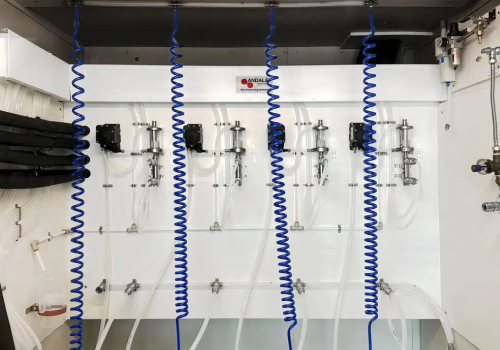

Glycol Block

Is a series of food grade stainless steel coils encased in aluminium. Glycol passes through the block and using the conducting properties of aluminium, the glycol block acts as a cold reservoir to cool the drink and stabilise the system. The glycol block has no moving parts and generates no heat and its compact size means it can be mounted behind glass racks or under the bar.

Glycol Tank

The Glycol Tank is usually placed in the cool room or cellar, chills the glycol and circulates the glycol through the python, font and glycol block and back again. Andale’s range of glycol tanks are made from fiberglass to prevent rust or corrosion and are proudly Australian made. Available in 3.5, 5, 8 and 10kw @ -10°C SST capacity. Each Andale glycol tank is available with two pumps (one on stand-by) and are available with either 70, 130 or 200 litre capacity.

Beerline Cleaning

A weekly cleaning cycle is recommended for our system. By using Andale’s Glycol Block Beer System beer is kept at a constant temperature from the keg to the tap, thus wild yeast and bacteria which thrive on heat, have a reduced chance of developing. Andale only use Valpar’s Brewmaster range of beerline tubing in our installations. Brewmaster has a nylon inner layer which is smooth as glass, therefore wild yeast and bacteria has a reduced chance of adhering to the inside of the beerline. Other types of beerlines have a rough or textured bore which allows the wild yeast and bacteria ample opportunity to adhere to the beerline.

At the End of the Nights Trading

Using the Glycol Block Beer Dispensing System and a cool room the only things that have to be done at the end of the nights trading is to turn off the gas system, in order to stop the kegs from over carbonating. When using Andale’s Glycol Block Beer Dispensing System, beer can be left in the beer lines 24 hours a day, 7 days a week, when used in conjunction with a cool room.

Glycol Beer System Upgrades

Andale have developed a range of Glycol Beer System upgrades that combine every element you need in a great Australian made Glycol Beer System. Andale’ system upgrades can save you money, reduce beer wastage, reduce gas consumption, increase the quality of your drink, improve the façade of your bar, monitor your usage and increase the safety of your cellar.

Q-guard Beer System

Andale have developed a range of Glycol Beer System upgrades that combine every element you need in a great Australian made Glycol Beer System. Andale’ system upgrades can save you money, reduce beer wastage, reduce gas consumption, increase the quality of your drink, improve the façade of your bar, monitor your usage and increase the safety of your cellar.

Beer Pump Gas System

Andale’s Beer Pump Gas System is design to save you money. How? By reducing gas consumption and on-going rental costs.

Smart Plates

Upgrading to Andale’s Smart Plate system is the only way to guarantee solid ice formation on your beer fonts. Ice formation on your beer fonts is a great selling point for ice cold tap beer.

Fonts

Andale’s font range is the most comprehensive in Australia. Andale have a font to suit every style of bar.

CONTACT ANDALE

Victoria

Showroom

5 King Street

Airport West, VIC, 3042

Tasmania

NSW

Showroom

2/2 Pile Road

Somersby, NSW, 2250

Western Australia

Queensland

Showroom

5 Holden Street

Woolloongabba

International

South Australia

Showroom

379 South Rd

Mile End South, SA, 5031